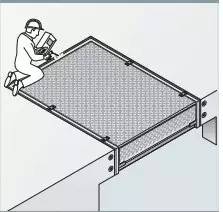

Air bag unloading platform

Wansheng air bag unloading platform by low-pressure high-capacity inflatable principle, through the rapid expansion of the air bag to enhance the table, power system using motors, fans, air bags, without high-pressure pump, simple and reliable, safe and efficient. Because of the structural characteristics of the air bag, the system does not need maintenance. The air bag with special fiber is treated by pest control, rodent control and common chemicals, so the air bag structure can be applied to all kinds of extremely cold, .

Airbag unloading platform manufacturers structure Technical performance:

1, up to 25 million times.

2, the United States imported high-speed powerful blower (current 10A, power 1.1kW), can adapt to cold, high temperature and other harsh temperatures (-50 ℃ / +65 ℃)

3, and equipped with air cleaning filter, which can effectively block dust, protect the motor and airbags.

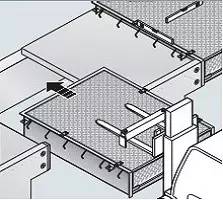

4, the air bag-type unloading platform loose-leaf board, is to rely on its weight down, the introduction of mechanical push rod structure, so that launch board more smoothly smooth, safe and reliable, and reset the board almost no noise.

5, the electric control operation is extremely simple: just press the button, the table will automatically rise, release the button, the unloading platform by gravity.

6, the air bag unloading platform almost no maintenance and repair, even if the airbag was accidentally punctured, airbag inflatable always greater than the amount of leakage, unloading platform at this time can still be used normally, but the rate of increase slightly slower, Also quite easy.

7, a unique shrinking legs, you can automatically unload the platform down to below the water level.

8, a patented design of the open-type loose-leaf joint, welded joints than the traditional pipe to increase the welding area of 300%, 2.5 times more force area, so that up to 4 times the sheet-lap increase in the bearing capacity; Easy to maintain.

9, patented design of the standard 28-ton support leg structure can be in the process of loading and unloading of goods, when the truck suddenly unloaded from the platform unloading area, support legs and forklifts can be kept in the water level, to ensure maximum safety and reduce accidents .

10, the table frame made of special I-beam, with a better force mode, and reduce the skeleton of the torque than the traditional channel to increase the bearing capacity of 2 times, more durable.

11, the front-end sheet by the high-strength anti-skid plate made of embossed; standard small plate thickness of 16mm, 8mm for the big board.

12, the unloading platform on both sides of the security baffle, yellow and black side of the warning strip, even when the maximum height of the table when the side panels can also ensure complete closure of the side, can effectively avoid the risk of crushing the toes , To ensure the safety of personnel.

13, with maintenance support rods, in order to maintain the maintenance of equipment maintenance unloading platform security.

14, the open base design, making it easier to clean up the pit position.

15, FASTLINK loading and unloading platform for lifting the whole lifting point and forklift unloading point.

16, the balance system Hardware and putter system using galvanized, anti-corrosion appearance.

17, the main structural parts are used high-quality high-pattern steel plate and profiles closely welded manufacturing, steel parts by a strict shot blasting rust surface treatment.

18, two primer, two finish, use high-quality polyurethane topcoat, film thickness of not less than 0.08mm, after drying.

Wansheng air bag unloading platform Product parameters:

1, up to 25 million times.

2, the United States imported high-speed powerful blower (current 10A, power 1.1kW), can adapt to cold, high temperature and other harsh temperatures (-50 ℃ / +65 ℃)

3, and equipped with air cleaning filter, which can effectively block dust, protect the motor and airbags.

4, the air bag-type unloading platform loose-leaf board, is to rely on its weight down, the introduction of mechanical push rod structure, so that launch board more smoothly smooth, safe and reliable, and reset the board almost no noise.

5, the electric control operation is extremely simple: just press the button, the table will automatically rise, release the button, the unloading platform by gravity.

6, the air bag unloading platform almost no maintenance and repair, even if the airbag was accidentally punctured, airbag inflatable always greater than the amount of leakage, unloading platform at this time can still be used normally, but the rate of increase slightly slower, Also quite easy.

7, a unique shrinking legs, you can automatically unload the platform down to below the water level.

8, a patented design of the open-type loose-leaf joint, welded joints than the traditional pipe to increase the welding area of 300%, 2.5 times more force area, so that up to 4 times the sheet-lap increase in the bearing capacity; Easy to maintain.

9, patented design of the standard 28-ton support leg structure can be in the process of loading and unloading of goods, when the truck suddenly unloaded from the platform unloading area, support legs and forklifts can be kept in the water level, to ensure maximum safety and reduce accidents .

10, the table frame made of special I-beam, with a better force mode, and reduce the skeleton of the torque than the traditional channel to increase the bearing capacity of 2 times, more durable.

11, the front-end sheet by the high-strength anti-skid plate made of embossed; standard small plate thickness of 16mm, 8mm for the big board.

12, the unloading platform on both sides of the security baffle, yellow and black side of the warning strip, even when the maximum height of the table when the side panels can also ensure complete closure of the side, can effectively avoid the risk of crushing the toes , To ensure the safety of personnel.

13, with maintenance support rods, in order to maintain the maintenance of equipment maintenance unloading platform security.

14, the open base design, making it easier to clean up the pit position.

15, FASTLINK loading and unloading platform for lifting the whole lifting point and forklift unloading point.

16, the balance system Hardware and putter system using galvanized, anti-corrosion appearance.

17, the main structural parts are used high-quality high-pattern steel plate and profiles closely welded manufacturing, steel parts by a strict shot blasting rust surface treatment.

18, two primer, two finish, use high-quality polyurethane topcoat, film thickness of not less than 0.08mm, after drying.